Page 1 of 1

Broken stud. Idea's of removal?

Posted: Mon Dec 28, 2009 2:51 pm

by dem0nk1d

So all day yesterday IÔÇÖve been trying to extract one of the exhaust bolts that bolt into the side of the case. The bolt has sheared off level with the case. IÔÇÖve tried drilling out and then using a Easy Out, which has snapped off into the stud. =) IÔÇÖm up for ideaÔÇÖs now. I also know for a fact that the Easy Out is hardened steel which is going to be harder than the hubs of * to get out. IÔÇÖve heard itÔÇÖs possible to weld a nut on top of the sheared bolt, and hopefully it should come out. Is there going to be any issues with heat transfer into the Aluminum case?

Re: Broken stud. Idea's of removal?

Posted: Mon Dec 28, 2009 5:42 pm

by mousewheels

Amateur welder here:

I've so far had good luck welding (MIG & Flux Core) flush studs on scooter cases and the below pressure washer (also aluminum). Some weld a washer with an undersize hole first, then put the nut on top and fill with weld. I find that advice helpful, it's easier to see & start the wire centered on the stud. Once got a fixer pressure washer with several head bolts sheared off at the case, but all came out ok.

Re: Broken stud. Idea's of removal?

Posted: Tue Dec 29, 2009 12:39 pm

by dem0nk1d

What do you think about studs that have broken off below the shear line? Example head-bolt. =) I have another issue with a whole different long block. I'm thinking I may have to drill out the hold bolt and use something like a Time-Sert / Heli-coil.

Re: Broken stud. Idea's of removal?

Posted: Tue Dec 29, 2009 3:05 pm

by devenex

I have the exact same situation, been holding up my Millenium Aero project for quite awhile. Probably just going to drop the block off at a shop here soon as I have no welding skills or equipment

Re: Broken stud. Idea's of removal?

Posted: Tue Dec 29, 2009 8:54 pm

by mousewheels

What do you think about studs that have broken off below the shear line? Example head-bolt. =) I have another issue with a whole different long block. I'm thinking I may have to drill out the hold bolt and use something like a Time-Sert / Heli-coil.

Well, I've never used the products - but there's special purpose stick welding electrodes for below surface repairs. The flux is said to coat the threads and prevent damage. Two company names I had a while back were Stoody and Coronatron.

Re: Broken stud. Idea's of removal?

Posted: Tue Dec 29, 2009 11:22 pm

by dem0nk1d

wow that's one * of a process. I have another engine that has one of the case holes fully stripped and looks to have a peace of the old head bolt stuck into it. This might be the thing to use, but d*** how much money will i need to dump into fixing one little hole.

always something. =)

Re: Broken stud. Idea's of removal?

Posted: Wed Dec 30, 2009 5:29 am

by veedubh20

spray wd40 let soak till lube is full, tiny little oil will down to buttom . and get Craftsman Drill Extractor

Re: Broken stud. Idea's of removal?

Posted: Wed Dec 30, 2009 1:05 pm

by mousewheels

I don't know how deep you need to dig to get the stud out. But have pulled them down to somewhere around 1/8" or so with the method below, and a wire feed welder. The flange of the weld tab is handy for centering up to a headbolt sized hole. The reduced dia is an aid in getting the weld started on the stud vs case.

Another idea: I've heard guys say they've used a copper tube as a sleeve to protect the threads.

Pics are a contrived 'broken stud'. If this were a stuck and broken stud, I'd weld a nut on top of that weld tab to put more heat into the stud, let it cool and squirt with penetrating oil.

Re: Broken stud. Idea's of removal?

Posted: Wed Dec 30, 2009 4:05 pm

by dem0nk1d

Last night I read somewhere about the copper tube method. The head bolt which looks to be stuck in the case, is probably has a little over ┬╝ material left, and is all the way at the bottom of the threaded hole. =) IÔÇÖm heading out for the New Years eve, but this weekend I should have time to think about which method IÔÇÖm going with on that scenario with that specific engine .

The other engine shouldnÔÇÖt be that hard as the broken bolts are probably within welding distance.

Re: Broken stud. Idea's of removal?

Posted: Fri Jan 08, 2010 3:47 am

by Trafficjamz

Re: Broken stud. Idea's of removal?

Posted: Mon Apr 26, 2010 2:48 am

by mousewheels

Demonkid - any updates on that ugly recessed broken bolt? I'd sure like to know how to fix such a break

Trafficjamz wrote:Snap-on has these extractors

Those look like gold. I like that they look so sturdy, the way the bite into those socket heads, and don't show a scratch.

I broke a 6mm bolt last weekend, and took a few tries to get the remainder of the bolt out. This was a saltwater beach bike, making some bolts a challenge to remove.

Once the bolt was broken off, part of the trick was getting enough heat into the bolt to break the corrosion free. Part of getting it unstuck was a great big ball of weld to put heat into the bolt. Eventually the bolt started moving a couple degrees. Finals tries were a washer welded to the bolt, with the oval tab welded on top. End result worked out, case is ok, threads ok.

-- Photos ---

A quick carb clean job just took a detour. Until that plastic cover comes off, there is no access to the carb mounting bolts.

- BrokenBolt2.JPG (30.58 KiB) Viewed 7011 times

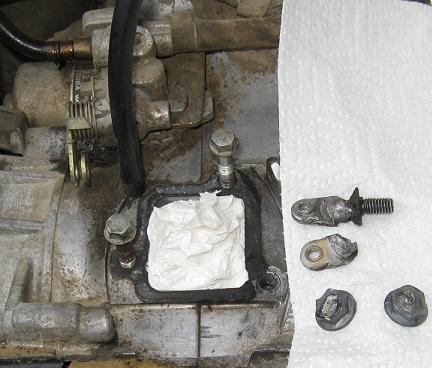

Bolt broken at the case. After the first couple extraction failures, the bolt was just below the case.

- BrokenBolt3.JPG (34.21 KiB) Viewed 7011 times

False confidence - was sure this one was going to be it.

- BrokenBolt4.JPG (32.7 KiB) Viewed 7012 times

Couple of the failed attempts at extracting the bolt, along with the successful extraction.

- BrokenBolt5.JPG (29.74 KiB) Viewed 7011 times

Re: Broken stud. Idea's of removal?

Posted: Mon Apr 26, 2010 1:56 pm

by Bear45-70

For a broken stub that you can't get out any other way and you want to save the case, there is the EDM process where the dissolve the steel bolt in the aluminum case without hurting the aluminum. I did this with some broken stubs on a high dollar racing gear case. Not cheap but it will save your aluminum case.

To prevent these broken bolts and studs try using this stuff. The last couple of super old outboards (1950's and early 60's) I worked on, this stuff prevented any broke bolts or studs and they were all steel bolts into aluminum.

" Various penetrating oils compared

Machinist's Workshop magazine actually tested penetrants for break out torque on rusted nuts. Significant results! They are below, as forwarded by an ex-student and professional machinist, Bud Baker.

*Don't forget the April 2007 "Machinist's Workshop" magazine comparison test.*

*They arranged a subjective test of all the popular penetrants with the control being the torque required to remove the nut from a "scientifically rusted" environment. *

Penetrating oil ....... Average load*

None ........................ 516 pounds

WD-40 ..................... 238 pounds

PB Blaster ............. 214 pounds

Liquid Wrench ..... 127 pounds

Kano Kroil .............106 pounds

ATF-Acetone mix..53 pounds

*The ATF-Acetone mix was a "home brew" mix of 50 - 50 automatic

transmission fluid and acetone.*

*Note the "home brew" was better than any commercial product in this one

particular test. Our local machinist group mixed up a batch and we all

now use it with equally good results. Note also that "Liquid Wrench" is

about as good as "Kroil" for about 20% of the price. *

*Your experience may vary, etc., etc."

The other thing you can do to prevent this from reoccurring is to Heli-Coil the holes in the aluminum before reassembly. Then you will have steel on steel threads instead of steel on aluminum. Guess which material wears the most?

Re: Broken stud. Idea's of removal?

Posted: Thu May 06, 2010 2:14 pm

by dem0nk1d

I tried welding a nut on the stud, and that sucker wasn't about to come off. How ever with the heat from the welder ending up breaking out the stud extractor. Then I decided to just drill the bolt out. So far so good. It's the lower exhaust bracket hole. I will either helicoil it, or just throw a nut on the other side and call it done.

Re: Broken stud. Idea's of removal?

Posted: Fri May 07, 2010 12:17 am

by mousewheels

dem0nk1d - thanks for the update, glad you have a happy ending.

Bear - thanks for the tips! This thread will get into the Wiki, along with that thread we had a while back about helicoils/timeserts etc for thread repair.

One more idea: There's a couple hits I got on using aluminum sulfate for steel stuck in aluminum. Here's one from Dans motorcycle. I'd like to try this sometime too.

----

"If you break off a tap in some kind of non-ferrous metal, like an aluminum crankcase, you can try soaking it in a solution of Aluminum Sulfate. It works best if you heat it to 120+ degrees Fahrenheit and let it work for a few hours. Or you can just throw it in at room temperature for a few days and the iron will go away. Remember, this is good for NON-FERROUS metals. Be sure there are no other iron pieces on the workpiece. Use a plastic tray, Tupperware works too. "

----