Page 1 of 1

Machining Cylinder Head

Posted: Tue Jul 03, 2007 1:26 pm

by HuskieMobileMan

How much should this cost to have done? One place told me $70! What a joke. How should I go about finding a place?

Posted: Tue Jul 03, 2007 2:52 pm

by Kenny_McCormic

idk but $70 is way to much to mill a head down. I dont think it would be more than $20

Posted: Tue Jul 03, 2007 4:03 pm

by chevyguyjay

what head is it? whats it go to? i could do it if its a spree or elite se50 head.

Posted: Wed Jul 04, 2007 1:33 am

by HuskieMobileMan

chevyguyjay wrote:what head is it? whats it go to? i could do it if its a spree or elite se50 head.

NH80, how would you do it? What kind of machinery do you have?

Posted: Wed Jul 04, 2007 2:19 am

by chevyguyjay

im not sure what the NH80 head looks like. on the spree head, i have a piece of steel about 4x4 and 3/4" thick. i drilled and tapped a hole in the center. i take the head and screw it down to the 4x4 steel plate with the fins of the head facing up. i put it on a magnetic surface grinder at work and mill the top of the head first. after i c that i milled all the fins, i flip it upside down and repeat the process. works great!

i milled 5, and ended up selling 3 of them.

Posted: Wed Jul 04, 2007 5:29 pm

by HuskieMobileMan

chevyguyjay wrote:im not sure what the NH80 head looks like. on the spree head, i have a piece of steel about 4x4 and 3/4" thick. i drilled and tapped a hole in the center. i take the head and screw it down to the 4x4 steel plate with the fins of the head facing up. i put it on a magnetic surface grinder at work and mill the top of the head first. after i c that i milled all the fins, i flip it upside down and repeat the process. works great!

i milled 5, and ended up selling 3 of them.

Do you mill the fins just so that you get a flat surface on the top?

Posted: Wed Jul 04, 2007 6:28 pm

by chevyguyjay

u got it.

Posted: Wed Jul 04, 2007 7:10 pm

by Kenny_McCormic

y would you mill the fins? That would make it run hotter on top of the increased heat after bumping up the compression

Posted: Wed Jul 04, 2007 7:20 pm

by chevyguyjay

well, take a stock spree head and lay it on a level surface with the fins down. if u notice, it has a wobble to it. i only mill just enough so i get all the fins. now that i know i got every fin, then i flip head upside down and mill the head.

Posted: Thu Jul 05, 2007 8:59 am

by noiseguy

Milling enough off the top to machine the bottom won't hurt anything; it's just using the equipment you have available. When I looked at milling the head I had the same problem.

We decided to use a lathe instead, using a similar jig to hold the head by the spark plug. This appears to be how they are done in production.

Posted: Thu Jul 05, 2007 3:43 pm

by Kenny_McCormic

oh now i get it your just removing casting defects not the entire fin

Posted: Thu Jul 05, 2007 4:11 pm

by chevyguyjay

:wink:

Posted: Sun Jul 15, 2007 1:51 pm

by chevyguyjay

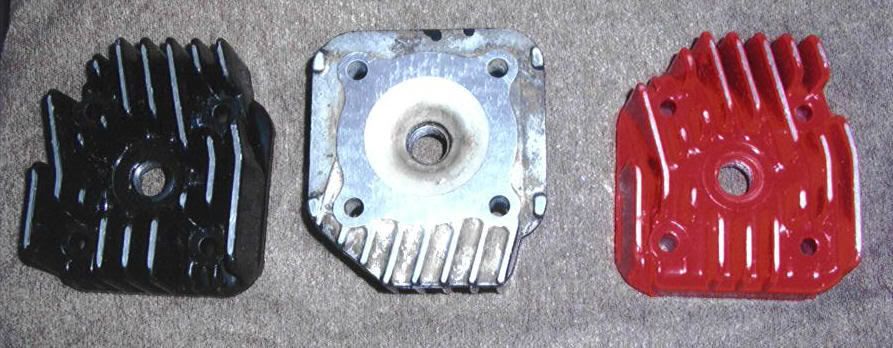

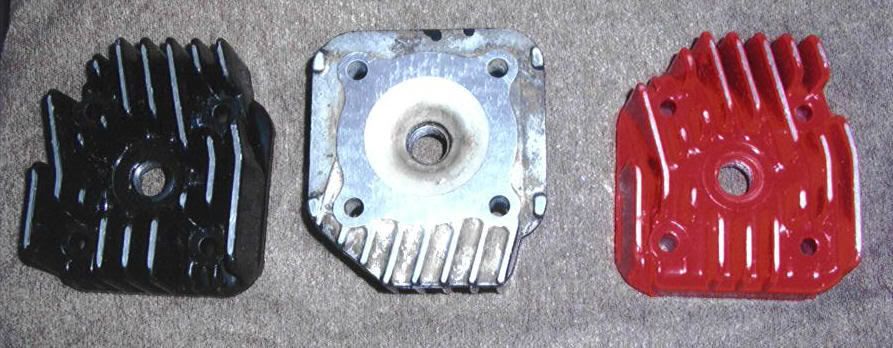

first thing i do is clean/ degrease the heads, then paint them with with a nice hard enamel finish. i machine these heads on a surface grinder. i start with the fin side up so i get that side level. then i flip it upside down and mill the head. pretty good results.

Posted: Tue Jul 24, 2007 12:16 am

by mousewheels

Nice pics, they finish off how you do the work. Great looking heads

Are you thinking about naming a price for another run of heads?

Do you think your jig can handle Gyro heads?

Noiseguy - thanks too - the lathe jig info is good. I didn't know how folks are doing the mods and dont have the equipment but its great to find out how its properly done.

thanks!

Posted: Tue Jul 24, 2007 2:32 am

by chevyguyjay

yea, the gyro head is going to be a little tricky. with those 2 studs, i might have to remove them and replace them with screws instead. i and going to do it though.......cant really think of any performance things to do to a gyro.

i milled 5, and ended up selling 3 of them.